Computer Systems Validation

MTS computer and software validation engineers will develop protocols and strategies to improve and qualify a structured lifecycle approach consistent with the Good Automated Manufacturing Practice (GAMP5) guidance.

MTS process is designed to ensure that your company is always in compliance with the applicable sections of the cGMP/GLP/GCP/ EMEA and 21 CFR Part 11. MTS will review supplier documents and your firms’ production mandates so to develop execution of requirements, specifications, design, safety, security, coding, testing, and installation and all acceptance criteria.

IQ/OQ/PQ Writing & Execution

MTS has a team of experts validation experts and comprehensive knowledge of FDA and European validation requirements. Our consultants come from a variety of backgrounds and understandings so as to address all possible complexities of your validation project.

MTS supplies all required cGMP documentation packages and will write clear, concise documents and implement IQ/OQ/PQ protocols for all manufacturers to ensure compliance mandates. Summary reports are provided for each protocol step and reflect raw data, graphs and other information so as to demonstrate the validation status of the items under quality and technical scrutiny.

Master Plan Development

MTS provides a complete Master Plan development with the approval and our customers. The Master Plan provides a documented standard and reference for all facility, equipment, methods and process validation components found within our customer sites. MTS will deploy the latest in regulatory requirements and criteria so as to provide our customers a Master Plan that is solid with technical and supportive documentation.

Preventative & Corrective Maintenance

MTS provides on-going and as needed preventative and corrective maintenance programs to support our customer process up-time, shutdowns and start-ups.

These programs can be in support of both quality and manufacturing requirements and scheduled throughout the year.

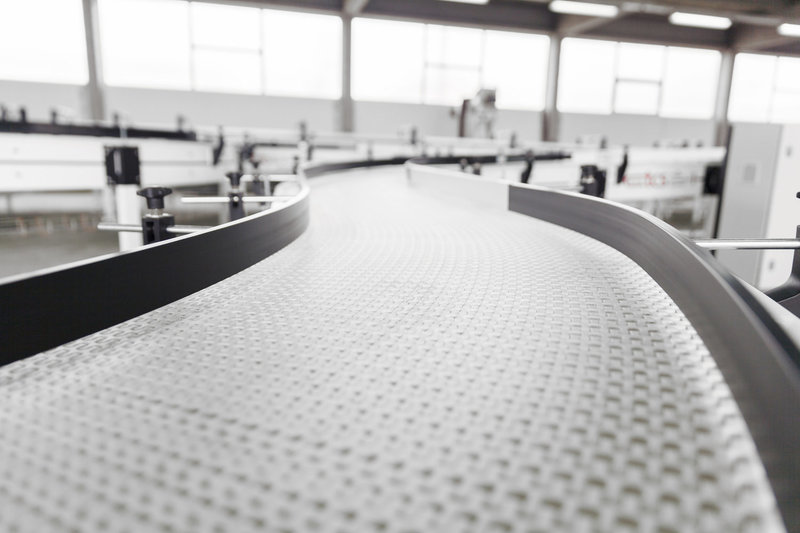

Process Validation

MTS through client-approved protocols provides documented evidence that a manufacturing process consistently produces a product that meets predetermined specifications and that the product progression is under quality control and monitoring. MTS can provide FDA and regulatory reviewable documents to prove that your products are safe, effective for your customers.

Thermal & Humidity Mapping

MTS will Temperature & Humidity Map Warehouses, Walk-Ins, Refrigerators, Autoclaves, Freezers and other temperature critical processes and equipment. MTS specialists provide fully traceably documentation utilizing calibrated and validated equipment and experienced personnel.